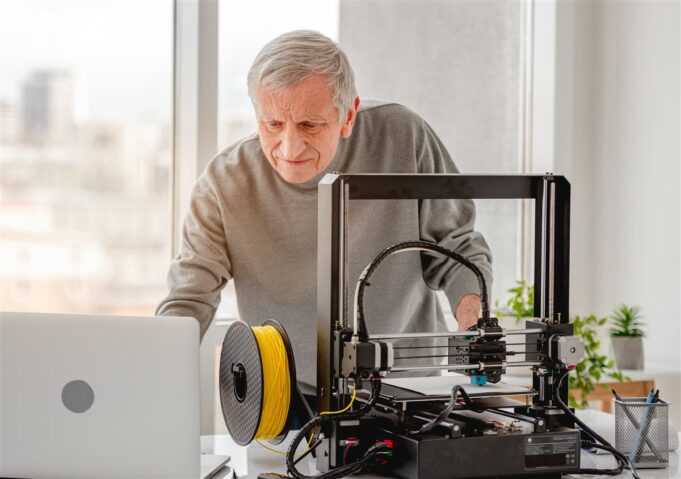

The world of manufacturing is constantly evolving thanks to technological advances. Among these technologies, 3D printing, and more specifically selective laser sintering (SLS) 3D printing, has established itself as a revolutionary solution to manufacturing challenges. This article details how SLS 3D printing offers innovative solutions through specific case studies.

The contribution of SLS 3D printing technology to product design

Designing new products is a critical process for any business. However, traditional manufacturing methods can limit innovation due to production constraints. Here, the use of SLS printing technology is a game changer.

SLS 3D printing offers unprecedented flexibility in product development. Engineers can experiment with various ideas without being limited by traditional production constraints. Design errors can be corrected simply by modifying the digital model and re-printing. In addition, this technology allows the production of complex parts that would be impossible to achieve with other manufacturing methods. The quality of parts produced by SLS printing is also remarkable, thanks to the precision of the process and the diversity of materials available for printing.

A concrete example is Protolabs’ use of SLS 3D printing for the manufacturing of medical device prototypes. Thanks to this technology, Protolabs was able to reduce development time and costs, while ensuring product quality.

SLS 3D Printing and the Biomedical Sector

The biomedical sector has particularly benefited from SLS 3D printing. This additive manufacturing technique has enabled the development of innovative solutions for the production of medical devices.

One of the main applications of SLS 3D printing in this field is the production of anatomical models for medical training. These models are of unmatched accuracy and can be customized to the specific needs of physicians. In addition, SLS 3D printing has enabled the manufacturing of custom-made medical devices, tailored to each patient. This has been particularly useful in the field of orthopedics, where each device must be adapted to the patient’s unique anatomy to ensure its effectiveness.

The impact of patenting on SLS 3D printing

Patenting is a crucial part of technological innovation. This is especially true for SLS 3D printing, where patents play a key role in the development of new materials and printing processes.

Patenting allows inventors to protect their innovations and encourage research and development. However, the patent landscape related to SLS 3D printing is complex and constantly evolving. For companies looking to use this technology, it is important to understand the implications of existing patents and develop an appropriate intellectual property strategy.

An interesting case study is that of HP and its “Jet Fusion” technology. HP has filed numerous patents related to this 3D printing technology, which has allowed it to stand out in the market and protect its innovations.

Towards an end use of SLS 3D printing

While SLS 3D printing was initially used primarily for prototyping, it is increasingly being used for the production of final parts. This trend is due to the constant improvements in SLS 3D printing technology, which now makes it possible to obtain high-quality, durable, and functional parts.

One of the main sectors that use SLS 3D printing for the production of final parts is the aerospace industry. This technology allows the production of lightweight and resistant parts, ideal for aerospace applications. In addition, SLS 3D printing offers the possibility of producing parts on demand, thus reducing storage and logistics costs.

There is no denying that SLS 3D printing has brought innovative solutions to various industries. Whether in product design, biomedical, patenting, or end-use, this technology has proven its potential and continues to push the boundaries of innovation.

The future of SLS 3D printing looks bright, with continued improvements in the technology and increasing adoption across various industries. SLS 3D printing will continue to play a key role in the evolution of manufacturing and technological innovation.