In these times of rapid technological progress, 3D printing presents itself as a revolutionary technique. It shakes up traditional design and production methods, offering almost infinite possibilities for manufacturing objects. Going from computer-aided design to the final object, we will demystify 3D printing in great detail.

Computer-aided design: the first step in 3D printing

3D printing begins with computer-aided design (CAD). This crucial step allows you to create a digital model that will serve as a basis for printing. In this phase, you can design any object in detail, defining its shape, size, proportions, and specific features.

The object to be printed is modeled in 3D using sophisticated software. The resulting digital model is then converted into a specific format for 3D printing, usually STL (Standard Tessellation Language). This file contains all the information needed to guide the printer during the printing process.

The 3D printing process: an innovative technology

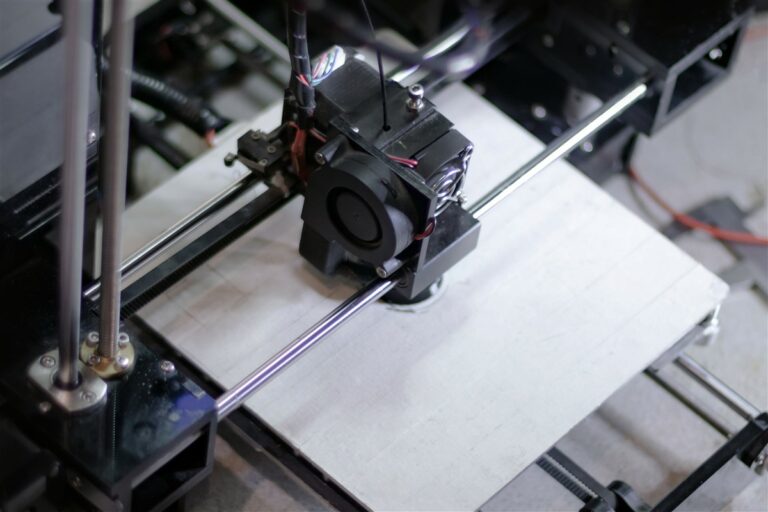

Once the digital model is finalized, comes the second phase: the actual 3D printing process. The STL file is imported into a slicing software, which slices the object into thin horizontal layers. These layers will serve as a guide for the printer during the manufacturing process.

3D printers use a variety of printing techniques. The most common is selective laser sintering (SLS), where a laser solidifies a powder to create the object layer by layer. There is also SLA printing, where a laser hardens a liquid resin, and wire extrusion, where a strand of material is melted and deposited layer by layer.

The choice of technique depends on the desired mechanical properties of the printed object, the required print quality, cost, and time available.

Surface finishing and post-processing: often neglected steps

After printing, the object is not quite ready yet. Often, it requires surface finishing and post-processing to achieve its final form. These steps are essential to improve the appearance and properties of the object.

Surface finishing may involve sanding, polishing, painting, or metalizing the object. This improves the visual appearance and feel of the object, and makes it more durable.

Post-processing, on the other hand, can include removing the print support, curing the object, quality control, and other necessary transformations. It is a crucial step to ensure that the printed object meets expectations in terms of quality and functionality.

The final object: a high-quality product

Finally, after all these steps, the final object is ready. 3D printing allows to produce high quality objects, with great precision and fidelity to the original digital model. In addition, thanks to additive manufacturing, it is possible to create complex and personalized shapes that would be difficult, if not impossible, to achieve with traditional manufacturing processes such as injection molding.

3D printing therefore offers many possibilities, both for professionals and enthusiasts. It allows you to quickly and inexpensively create prototypes, spare parts, art objects, jewelry, toys, and many other things.

3D printing, from computer-aided design to the final object, is an innovative technology that is revolutionizing the way we design and produce objects. It offers unlimited creative possibilities, with great precision and flexibility. However, it also requires a good understanding of CAD, printing materials, printing parameters and post-processing techniques to achieve high-quality results.

With the advent of 3D printing, we can all become manufacturers, creating unique and personalized objects. It’s a revolution in progress, which promises to transform the way we design, produce, and consume. So, are you ready to embark on the adventure of 3D printing?

Comments 1